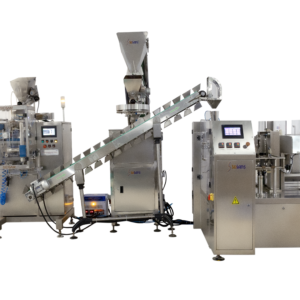

Capping Machine is a precision-engineered solution for automatically sealing caps on a wide range of containers including bottles, jars, and vials. Designed for industries like food & beverage, pharmaceuticals, cosmetics, and chemicals, this machine ensures consistent, leak-proof closures with every cycle.

Available in rotary, inline, or semi-automatic models, the system supports screw caps, ROPP caps, press-fit caps, and snap-on closures. It features torque adjustment, cap orientation, and height flexibility for compatibility with different container sizes and shapes.

With its stainless-steel body, PLC control system, and integrated conveyor, the Capping Machine is ideal for high-volume production lines. It minimizes downtime, reduces manual labor, and improves packaging consistency.

Whether you’re automating a startup bottling operation or scaling up an industrial filling line, our capping solutions provide reliable sealing performance. Used globally across FMCG, pharma, and cosmetics industries, this machine increases production speed while ensuring cap integrity.

Reviews

There are no reviews yet.